Hello from Oakland!

TL;DR: Got a bunch of quotes. Eliminated all but two potential manufacturers. Checking references now. Jesse’s probably spending July in Shenzhen doing DFM and getting set for manufacturing, with a goal of shipping keyboards this fall (assuming no more than one major catastrophe.)

Collecting quotes

Over the last month, we received sales quotations from almost everybody Jesse visited while in Taiwan and China.

After signing an NDA, we sent each factory the same bid packet. Included were a full Bill of Materials, Schematics, PCB layouts, 2D drawings of mechanical parts, 3D models of mechanical parts and a fifty page ‘Product Requirements’ document spelling out everything about how to make the Model 01 and why we made those design decisions.

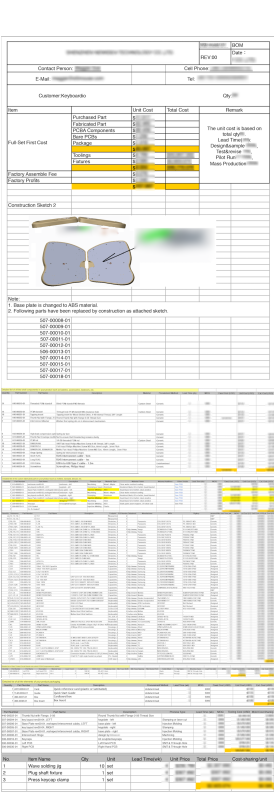

We asked each factory to send us a project proposal including a quotation with a 'costed BOM.’ That is, we asked them to take our spreadsheet spelling out each and every component and tag it with a lead time, a unit cost, and a tooling cost if applicable. The costed BOM helps make sure that everybody agrees about what’s going into the product and helps make us make sure that the quoted price actually adds up. We also asked for a bunch of detail about their corporate history, certifications, credit references, and materials management policies. These were things that a consultant helping us with the bid process assured us were pretty standard. As it turns out, they are standard for larger factories, but a little bit daunting for most of the folks we’re talking to. Only two factories actually sent us costed BOMs, which are a hard requirement for us to move forward with a manufacturer. Not too surprisingly, nobody filled in the detailed questionnaire. Only one factory even mentioned that they’d read it and asked if they had to fill it in. For the factories we’re serious about, we’re working through the important bits of the questionnaire by asking them questions a few at a time.

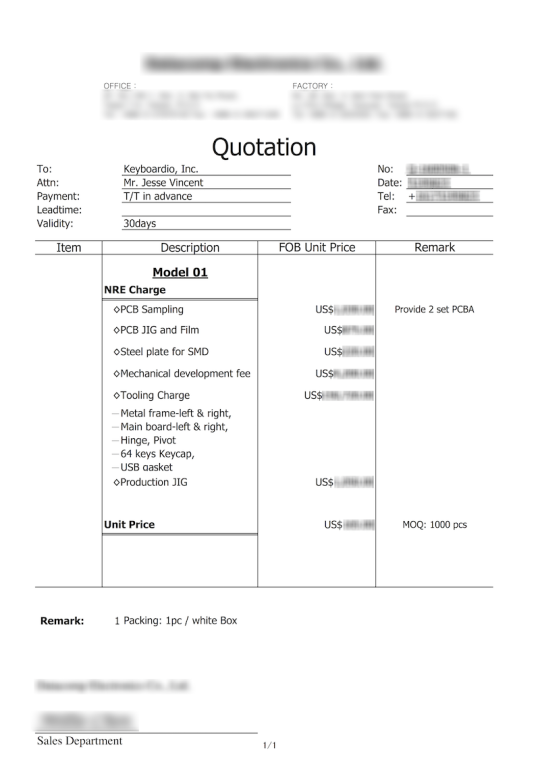

An example of the kind of quotation you don’t want to get for a six-figure manufacturing project.

One of the factories we initially thought to be among the most promising options sent a design proposal for our interconnect hinge that didn’t actually meet the design requirements and…never replied to our request for clarification. One of the factories we knew we weren’t going to go with sent a three-line email with a very round number as their rough estimate for unit costs. One of the larger factories sent an estimate for the tooling costs for some of the mechanical parts and said they couldn’t figure out some of the engineering and couldn’t bid on the full project unless we found someone else to do that bit of the design. One of the manufacturers submitted a bid that included six months of full time Electrical Engineering and Mechanical Engineering staff as part of the run-up to manufacturing. One of the most reputable manufacturers sent us a single-page quotation.

Picking a manufacturer

And then there were the other two. The largest, most automated keyboard factory we visited and the smallest both sent us the 'costed BOMs’ we’d asked for. They were, conveniently, the two manufacturers we had the best feeling about coming out of our meeting.

A quotation that made us smile. The manufacturer took our bill of materials, added pricing, an overview page and noted places where their design proposal deviated from what we’d asked for. They broke out their overhead and specified lead times.

For the past couple weeks, we’ve been trying to do our diligence on the two candidate factories. That includes everything from asking them for reference customers to web-stalking products we know them to be the OEM for.

There are tradeoffs to going with either manufacturer.

The larger factory is incredibly well automated. The salesperson we’re working with is friendly. As a company, they mostly work with Chinese customers. Because neither of us speak more than a few words of Mandarin, communication with them is mostly through translators and intermediaries. Their proposed pricing is significantly more expensive than the smaller factory’s proposal. We’re primarily working with a junior salesperson, who would also be our project manager if we signed with them. We would definitely be one of their smallest customers. When we visited the factory, we weren’t able to meet with the General Manager.

The smaller factory is much less automated than the larger factory. The salesperson we’re working with is friendly and has been incredibly responsive throughout the bid process. Like most of her team, her spoken and written English is great. Their pricing is much, much better than the larger factory’s. (It’s not the lowest quote we’ve gotten but is on par with the pricing we got from the factory that ditched us.) The General Manager is also their engineering lead. He was actively involved in the design meeting when Jesse visited in April. The downside is that they’re less automated than the larger factory and that the folks at HWTrek aren’t yet convinced that their in-house quality management processes are well-enough documented (and adhered to). That said, we already own at least one perfectly reasonable product that was (unbeknownst to us when we bought it) made in this factory.

At this point, we’re leaning hard toward selecting the smaller manufacturer and bringing in a third party to help put together quality documentation and to provide an extra layer of QC at the end of the production line. Their responsiveness, management involvement and the fact that we’d not be their smallest customer all contribute to a feeling that they’d be a better fit for us. While cost is certainly an issue, their current quote actually gives us some wiggle room to find ways to make your keyboard even nicer.

We’d hoped to have finished checking their references this week, but ran into the Chinese Dragon Boat Festival holiday. Dragon Boats willing, reference checks will happen next week. From there, we’ll send them back a draft of a Letter of Understanding (LoU) that spells out enough of the manufacturing contract terms to put down a deposit and stick Jesse on a plane to China.

The current plan is for Jesse to spend the bulk of July in Shenzhen working with whichever manufacturer we select to finalize the manufacturing design for the Model 01. That includes sorting out the interconnect and feet once and for all and making sure that we’re all on the same page about how the keyboard gets made. The goal is to come back from China with a final prototype keyboard and a thumbs up for the manufacturer to start cutting steel to make injection molds.

Wood Samples

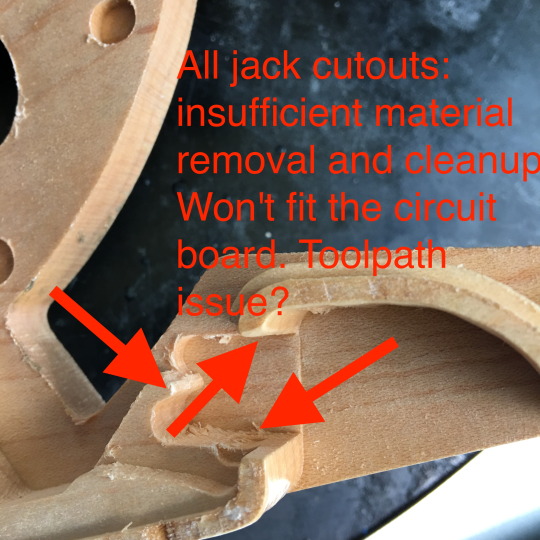

When we last wrote, we’d just received quotes from the two wood factories Jesse visited in Shenzhen. We were surprised how affordable the quote from the 'nicer-seeming’ of the two factories was. When they offered to make us samples to show off their abilities, we leapt at the chance. The samples showed up just before Maker Faire. All of them had visible milling toolpath marks. None were anywhere close to the tolerances we’d specified. Several hadn’t even been deburred on the inside. One sample showed visible drips of varnish. One was cracked.

Varnish this uneven suggests that the manufacturer was laying it on a little thick.

This low-quality milling never should have left the shop floor.

We asked the manufacturer what the deal was and they told us that they were trying to show us 'typical’ quality, rather than 'best quality’, so as not to surprise us when we got to manufacturing. After we sent them pictures showing off all the issues, they told us that making nice-looking parts would cost more, but that they’d do the first production run at the price they originally quoted. They promised to send us additional samples the next week. It’s been three weeks.

On the upside, this makes our choice for a primary manufacturer for the wood parts easy. The other wood factory sent us nice looking samples months ago and Jesse was able to verify the quality of other products coming out of their woodshed.

Maker Faire!

Maker Faire!

Last month, Kickstarter invited us to show off the Model 01 prototypes at the Bay Area Maker Faire. We had a great time, even though Jesse pretty much lost his voice. A bunch of backers we hadn’t yet met came by to say hi. And we won TWO editors’ choice blue ribbons. We had a lot of engineering-focused discussions, but the toughest technical grilling we got was from a nine-year-old.

We won a couple shiny blue ribbons!

Maker Faire always feels like home. Many, many attendees are pretty squarely in our core demographic of “people who care about open hardware and type too much.”

We shouldn’t have been surprised when the Model 01 was discovered by a very different set of new fans at Maker Faire.

In retrospect, it is completely obvious that a butterfly-shaped rainbow keyboard would be popular with tween girls. (And their Maker Faire-attending parents like that customizing the LED effects requires learning a bit of programming.)

Until next month,

<3 j + k